Category

Custom Alloy Aluminium Pressure Die Casting Gravity Casting with Anodizing Surface

Overview Product DescriptionDetailed Photos Certifications Company Profile NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY w

Overview

Company Profile

NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY was established in 2001. BOLANG centres high precision CNC machining as our core competence, the company specializes in producing auto parts, agriculture parts, machinery parts, lighting parts, hardware fittings etc. We can provide pressure casting, sand casting, investment casting, gravity casting, the material covers aluminum alloy such as A380, A390, ADC12,YL102, A356, aluminum extrusion of 6000 series, zinc alloy, iron, copper etc.

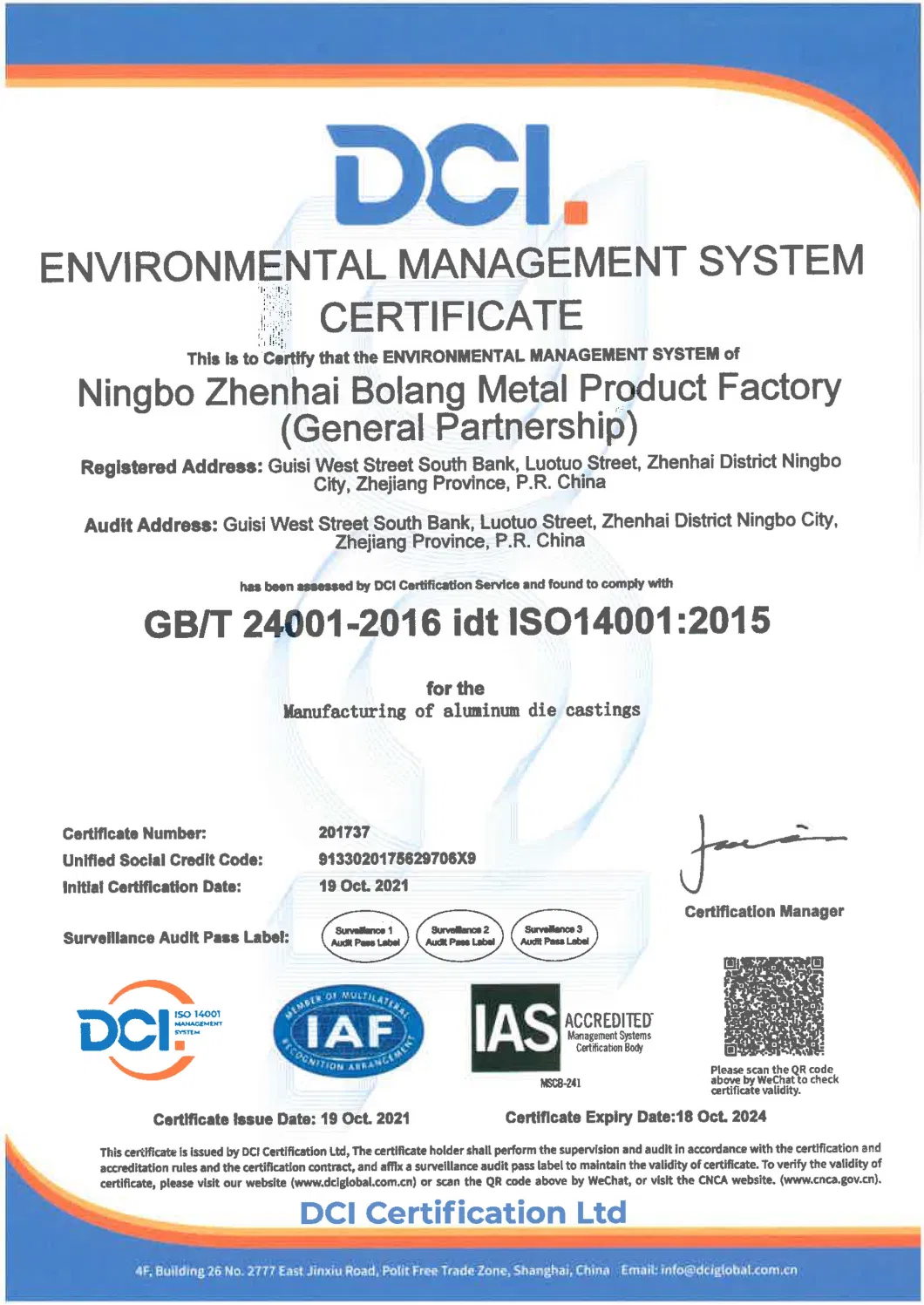

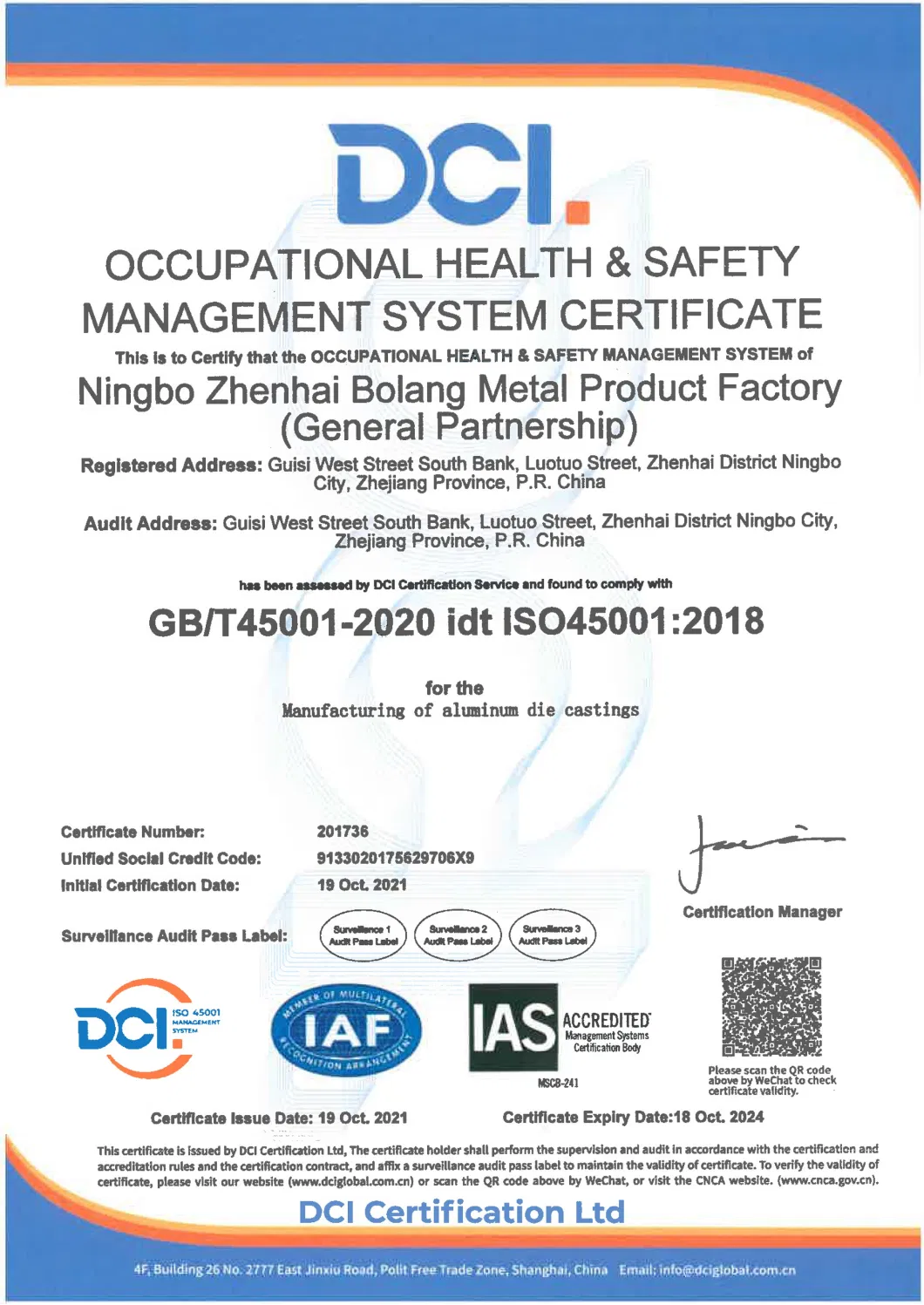

The products are mainly exported to countries such as USA, Europe (England, Germany, Italy, Belgium etc), Asia (Japan,Korea etc). And the company has successfully passed ISO/TS16949 quality management certificate,ISO45001,ISO14001 certificate.

FAQ

Basic Info.

| Model NO. | bl39 |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 2 |

| Certification | IATF16949:2016,ISO45001,ISO14001 |

| Software Applied | PRO/E, Auto CAD, Solid Work 2013, Ug |

| Surface Finish | Coating, Anodizing, Shot Blasting, Polish |

| Machining Fixture | Fixture Design and Fabrication |

| Mold | Mold Design and Fabrication |

| Transport Package | Carton, Environmental Pallet |

| Specification | Customized |

| Trademark | Customized |

| Origin | Ningbo |

| HS Code | 8708999990 |

| Production Capacity | 100000PCS/Year |

Product Description

Product DescriptionDetailed Photos

Company Profile

NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY was established in 2001. BOLANG centres high precision CNC machining as our core competence, the company specializes in producing auto parts, agriculture parts, machinery parts, lighting parts, hardware fittings etc. We can provide pressure casting, sand casting, investment casting, gravity casting, the material covers aluminum alloy such as A380, A390, ADC12,YL102, A356, aluminum extrusion of 6000 series, zinc alloy, iron, copper etc.

The products are mainly exported to countries such as USA, Europe (England, Germany, Italy, Belgium etc), Asia (Japan,Korea etc). And the company has successfully passed ISO/TS16949 quality management certificate,ISO45001,ISO14001 certificate.

FAQ

| FAQ |

| Q1. When can I get the price? |

| A: We usually quote within 2-3 days after we receive the RFQ or feedback within 2 days if any questions on prints need to be confirmed. |

| Q2. How long is the lead-time for mold? |

| A: Usually it depends on the size and complexity of the mold. But normally, the lead time is 35-45days. |

| Q3. I have no 3D drawing, how should I start the new project? |

| A: You can supply us a sample, we will help work on establishing 3D model accordingly. |

| Q4. Before shipment, how to ensure the products quality? |

| A: We have strict development procedure, during samples development, we have capacity to produce according to PPA, after PSW approved, |