Category

Investment Casting Parts

Package Size 20.00cm * 30.00cm * 10.00cm Package Gross Weight 2.000kg ABOUT US Ningbo Suijin machinery Technology Co,.Lt

Basic Info.

| Model NO. | SJ00492 |

| Application | Valve / Pump |

| Material | Alloy Steel |

| Surface Preparation | Shot Blasting |

| Surface Roughness | Ra1.6 |

| Machining Tolerance | +/-0.01mm |

| Standard | DIN |

| Certification | ISO 9001:2000, IATF16949 |

| Surface Treatment | According to Cutomer Request |

| Surface Color | N/a |

| Weight | 0.005-20kg |

| Packaging | Standard Packaging with Carton Box and Pallet |

| Transport Package | Carton Box+Wooden Pallet |

| Specification | N/A |

| Trademark | SJ |

| Origin | Zhejiang, China |

| Production Capacity | 500000/Year |

Packaging & Delivery

Package Size 20.00cm * 30.00cm * 10.00cm Package Gross Weight 2.000kgProduct Description

ABOUT USNingbo Suijin machinery Technology Co,.Ltd is a profational manufacturer in Ningbo city, our main process is investment casting/precision casting and machining, for casting process, we have two kinds of production line, one is precision casting, another is water glass with competitive cost.Apart from the investment casting workshop and machine workshop, we also provide the sand casting parts to meet the requirement for varial demand from our customer.

CERTIFICATIONS

Our company got the ISO9001 and IATF16949 certification, and aslo we are awarded the new high-tech enterprice by Chinese government, and we have more than 20 patent.

ADVANTAGES

• More than 10 years experience on casting and machining • Advanced inspection equipment to ensure the tolerance • Flexible PO QTY to meet customer demand • Professional engineers in casting and machining • Competitive price and exllent parts quality • Nearby Ningbo port, on-time delivery

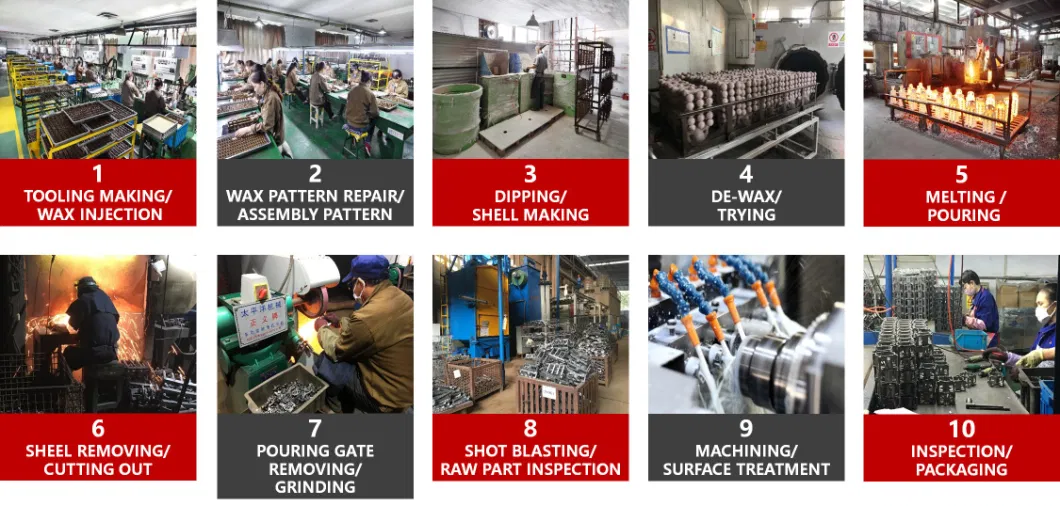

PROCESS FLOW

OEM&ODM SERVICE

Ningbo suijin machinery technology can provide the ODM&OEM service for customer, and main is ODM, we can manufacturing the customized parts according to 2D&3D, we have professional R&D team can take part in ealier development phase of the project.

AVALIABLE MATERIA & SURFACE TREATMENT

| Avaliable Material | |||

| Carbon Steel | Alloy Steel | High Chromium Cast Iron | Low carbon steel |

| Stainless Steel | Duplex Stainless Steel | Steel bar | Ductile Cast Iron |

| Surface treatment | |||

| Heat Treatment | Zinc Coating | Blackening | Mirror Polishing |

| Satin Polishing | Electrolytic Polishing | Shot Peening | DACROMET |

PRODUCT APPLICATION

AUTO PARTS

• Exhaust inlet/outlet cone • Shift sleeve • Fuel rail bracket • Tempreture sensor boss • Mounting Brackets • Oxygen sensor boss • Brake balance block • EGR sensor boss • Exhaust valve body

ARCHITECTURAL HARDWARE

• Mounting Base • Mounting plate • Bearing Covers • Coupling • Grount sleeve • Sprockets • Handle • law glass curtain wall accessories • Side Plates

AGRICULTURAL MACHINERY PARTS

• Tooth Blocks • Track shoes • Bucket Teeth • Track Links • Clamping • Mounting Brackets • Lifting Eyes • Quick Joint • Trencher Tooth

MARINE HARDWARE • Star handle • Door hinge • Folding Dock Cleat • Mirror Polished Mooring • Hollow base boat rope cleat • Mounting Brackets

VALAVE/PUMP

• Valve body • Explosion-proof valves • Pipe fitting

OTHERS

The casting part is wildly use in the industries, such as rail&transit parts, bicycle parts, casting impeller, food machine sorting components, solar mounting system parts, container safety parts, Electronic lock body, robot parts and so on, we have more than 20 patents related to this kinds of project in production.

ADVANCED EQUIPMENTS

Our company also equiped advance inspection equipment to meet the inspection requirement of the parts, so that we can sure the part can have a good quality.

MAIN EQUIPMENT LIST

| Magnetic defect inspection | Spectrometer | HB hardness inspection | Mechanical inspection |

| Ultrasonic defect inspection | Roughness tester | HR hardness inspection | CMM inspection |

| Metallographic detector | X-ray inspection | Dye penetrant inspection | 100% Thread inspection |

FAQ

| Q1 | Are you factory or trading company? |

| A1 | We are factory located in Ningbo city, China |

| Q2 | What kinds of language is avaliable? |

| A2 | English, Chinese, except email cummunication, we are ok with video meeting and calling. |

| Q3 | How should I place an order? |

| A3 | We are receive the PO and production drawing by email. |

| Q4 | Which shipping methed is ok for you? |

| A4 | Normally shipping by sea and train is use for mass production order delivery. DHL,TNT,FedEx, UPS,EMS air shipment is use for sample delivery. |

| Q5 | How can I contact you? |

| A5 | You can contact us by email, and also we can chat by Skype, Teams, WhatsApp, Facebook. |

| Q6 | What kinds of drawing format can be use? |

| A6 | PRO/E, Auto CAD, Solid Works, IGS, UG, CAD/CAM/CAE, STEP. |

| Q7 | Which packing material do you use for sea shipping? |

| A7 | For sea shipping, we will packaging with European standard wooden pallet. The parts will packing with PE bag inside the carton box. |

| Q8 | How do you deal with the RFQ? |

| A8 | Sales receiving the RFQ---Feasiblity study meeting with R&D engineer---Feed back technical issues with Customer---Sales quoted |