Category

OEM Metal Part Auto Stamped Part Stainless Steel Metal Processing Precision Stamping Metal Fabrication Automobile Precious Metal Hardware Stamping Part

OEM Metal Part Auto Stamped Part Stainless Steel Metal Processing Precision Stamping Metal Fabrication Automobile Precio

Basic Info.

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.1mm |

| Customized | Customized |

| Tolerance | ISO2768-F |

| Surface Treatment | Painting/Powder Coating/Sand Blast/Anodise |

| Transport Package | Plywood |

| Origin | Qingdao |

| HS Code | 7326909000 |

| Production Capacity | 500ton |

Product Description

OEM Metal Part Auto Stamped Part Stainless Steel Metal Processing Precision Stamping Metal Fabrication Automobile Precious Metal Hardware Stamping Part

| Product Material | Q235/ Q345/ C10/ C20/ C45/ 16Mn etc.AL6061/ AL6063/ AL5754/ AL5052 etc.SUS201/ SUS303/ SUS304/ SUS316/ SUS316L etc.H57/ H58/ H59/ H62 etc. |

| Accuracy | 0.1mm |

| Capacity | Parts :1million /month |

| Design software | 3D:PROE/ UG/ SOLIDWORKS 2D: AutoCAD/ PDF/JPEG |

| Surface Treatment | Powder coating/ Hot galvanized/ Painting/ Polishing/ Brushing/ Chrome plating/ Nickel plated etc. |

| Test Equipment | Hardness tester/ Chemical analysis/ Digital Measuring Projector etc. |

| Thickness | 0.1-20mm or other special available |

| Lead time | 15-50 days according to products |

| Standard | ANSI/ API/ BS/ DIN/ JIS/ GB etc. |

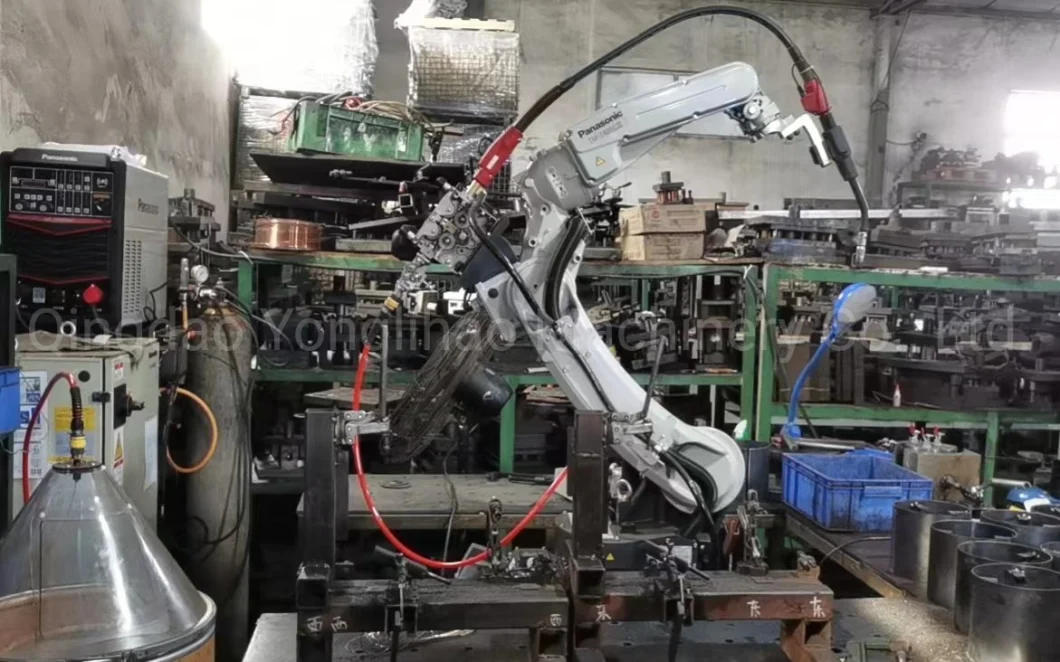

| Equipment |

|

| Productions Cover | Light product/ Construction industry product/ Valve product/ Auto spare product/ Motor car products/ Equipment spare product/ Furniture products etc. |

Product Display

Advantage of metal stamping:

(1) The stamping parts have high precision sizes and are consistent with the die size. General assembly and use requirements can be met without further machining.(2) Generally, cold stamping parts are no longer machining, or only need a small amount of machining.(3) During the stamping process, the material surface is not damaged, so it has good surface quality, smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphate, powder spraying and other surface treatment.(4) The stamping parts are manufactured by stamping on the premise of low material consumption. The parts are light in weight and have good rigidity. After plastic deformation, the internal structure of the metal is improved, so that the strength of the stamping parts is improved.(5) Compared with castings and forgings, stamping parts are thin, uniform, light and strong. Stamping can produce workpieces with stiffeners, ribs, undulations or flanging that are difficult to manufacture by other methods, so as to improve their rigidity.

Production Process

Quality Control

In Yonglihao, every staff emphasizes quality is first. Testing report and samples of all products will be kept by our quality control department.>> Receiving inspection to raw materialAll materials must be provided with suppliers' certificates, and have to pass the receiving inspection before starting production. Occasionally, material samples will be sent to independent lab for specific test to meet customers' demands. All materials have to be tagged and classified, so the original source could be traced at any time during production processes.>> Producing inspectionEvery phase of production processes will be monitored by producing inspection. The first product shall accept test in every phase of production process. Only it completes the test and confirmed by quality control manager, mass production could be operated. Every producing operator will implement constant tests during production processes, including size-measuring, observing the appearance. >>Final inspectionProducts of Yonglihao only can get out of the warehouses after all files signed and sealed.

Warehouse and Shipment

RFQ:

Q1:Where can I get product & price information?A1:Send us inquiry e-mail or add us whatsapp, we will contact you as we receive your mail. Q2:How long can i get the sample?A2:Depends on your specific items, within 3-7 days is required generally.Q3:What kinds of information you need for quote?A3:Kindly please provide the product drawing in PDF, and will be better you can provide 3D drawing in STEP or IGS format.Q4: What shall we do if we do not have drawings?A4:Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Length, Hight, Width), CAD or 3D file will be made for you if placed order.Q5: How can we know the chemical component of your products is according to our request?A5: When we offer samples or batch parts, we will also send you our material list from our material factory, it shows more detailed.Q6: How to guarantee your final size can meet our drawing request?A6: we will make moulds according to your 3D drawing. And we also do sampling when batch production start, to make sure the final dimension can meet your request.Q7: How to make sure the color after painting or powder coating can be correct?A7: We have color card with different color number, such as RAL9016, we will contrast the sample surface and color card, to make sure the final surface effect is correct.Q8: Generally, how do you packing the goods?A8: normally, for inner package: the goods is nude, for outer package: carton + plywood. Q9: If we find the defect products exist in the batch parts, how to do?A9: Yes,your caution is very good, in fact, when batch production, we need do sampling. Before shipment, we also do testing to make sure the quality is ok. If you found several defect product exists, pls take photos and send your quality feedback, we will check and send you qualified products. But pls be assured that our products is qualified, unless caused by the worker's mistake to place.