Category

Hot Open Die Forging Hollow

Overview Package Size 1200.00cm * 1000.00cm * 500.00cm Package Gross Weight 20000.000kg Our forged steel sheave wheels a

Overview

Basic Info.

| Model NO. | custom |

| Application | Machinery Parts |

| Material | Steel |

| Heat Treatment | Quenching |

| Surface Treatment | Powder Coating |

| Forging Tolerance | +/-0.5mm |

| Standard | All Standards |

| Certification | RoHS, ISO 9001:2000 |

| Transport Package | Custom |

| Specification | custom |

| Trademark | custom |

| Origin | China |

| Production Capacity | 10000/Year |

Packaging & Delivery

Package Size 1200.00cm * 1000.00cm * 500.00cm Package Gross Weight 20000.000kgProduct Description

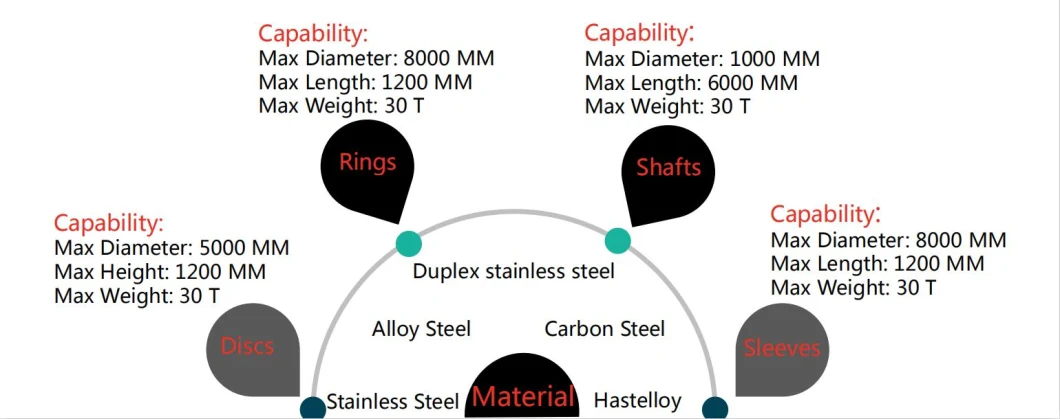

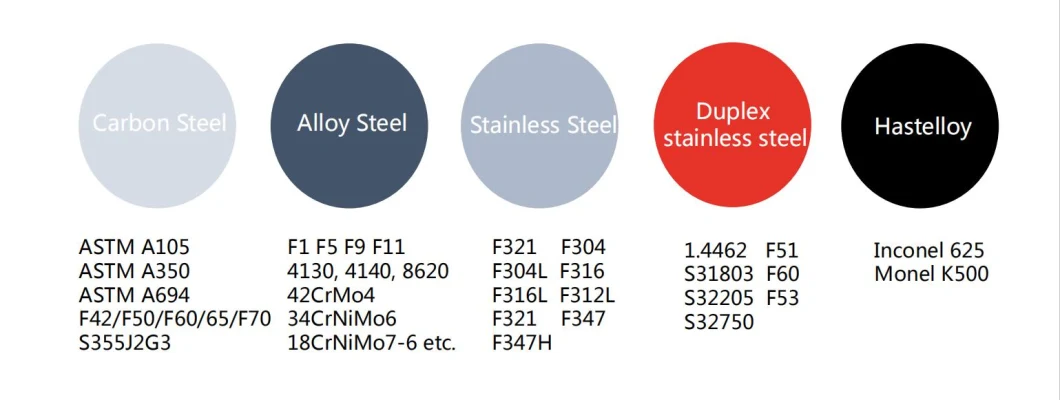

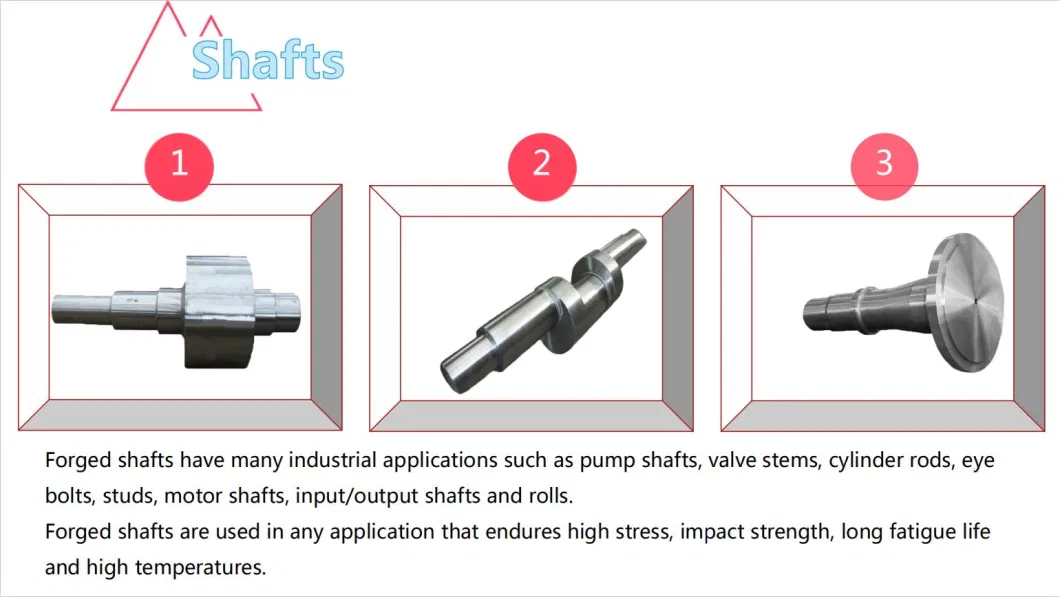

Our forged steel sheave wheels are available in a wide range of standard sizes. At the same time, we can produce forged sheaves according to customer's drawings and technical requirements.The heat treatment and surface treatment for forged steel sheaves will be performed according to customer's requirements.Material: stainless steel, carbon steel, alloy steel, titanium alloy, aluminum, copper.Diameter size: from 50MM to 2000MM.Weight: from 0.5KG to 15000KG.Product Description

| Mold Materials | Die steel |

| Materials | Stainless steel, carbon steel, alloy steel, aluminum , copper, titanium. |

| Part Weight | From 500g --- 30000kg. |

| Surface Treatment | Mill-Finished, Powder Coating, Polishing, Brushing, Etc. |

| Drawing Format | IGES, STEP, Auto CAD, Solidworks, STL, PTC Creo, DWG, PDF, Etc. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling. |

| Application | Industrial, Consumer, Food Processing, Aviation, Seals/Gaskets, Lighting, Packaging, Filter, Healthcare, Telecommunications,Mechanical, Water Treatment, Appliance, Recreation, Lawn And Garden, Educational, Oil And Gas, Government, Construction, Plumbing,Surveillance, Pumps,Marine,Motors,Gears, RFID Tags, Electronics, And Fasteners. |

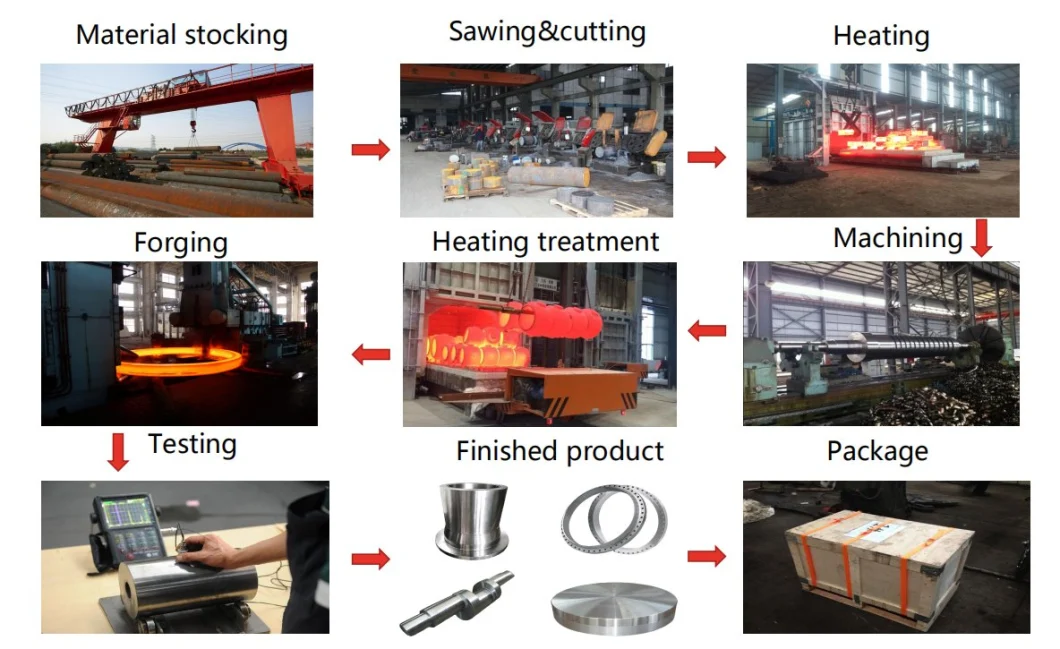

Production Process

Detailed Photos

Company Profile

Shanxi KSN Precision Forging Technology Development Co., Ltd.It was established in 2005, located in Taiyuan City, Shanxi Province, is a professional manufacturer and exporter of precision forging products. KSN focuses on different types of free forging, open forging and precision closed forging, has accumulated a lot of practical forging experience and technical support. Nearly 95% of the products are exported to Europe, the United States, the Middle East, Southeast Asia and other countries.Production Capacity

Testing Ability

Packaging & Shipping

Our Advantages

Previous: Mianxuan Manufacturer Hot Customized Auto Parts OEM Iron Steel Stainless Precision Investment Motor Housing Forging Aluminum Die Lost Casting Parts

Next: Sample Customization Factory Alloy Steel Hot Die Forging Part for Steering Knuckle Auto/ Truck/Motorcycle Parts From 10kg to 300kg

Send inquiry

Send